Chain link fences are ubiquitous in various applications, from residential boundaries to high-security facilities. These fences offer durability, cost-effectiveness, and versatility, making them a popular choice for property enclosures. Understanding the manufacturing process of chain link fences provides insight into their construction and quality. In this guide, we'll explore how chain link fences are made, from raw materials to the finished product.

The manufacturing process of chain link fences begins with the selection of raw materials. The primary material used is galvanized steel wire, which offers corrosion resistance and strength. The wire typically comes in large coils and is sourced from reputable suppliers to ensure quality and consistency.

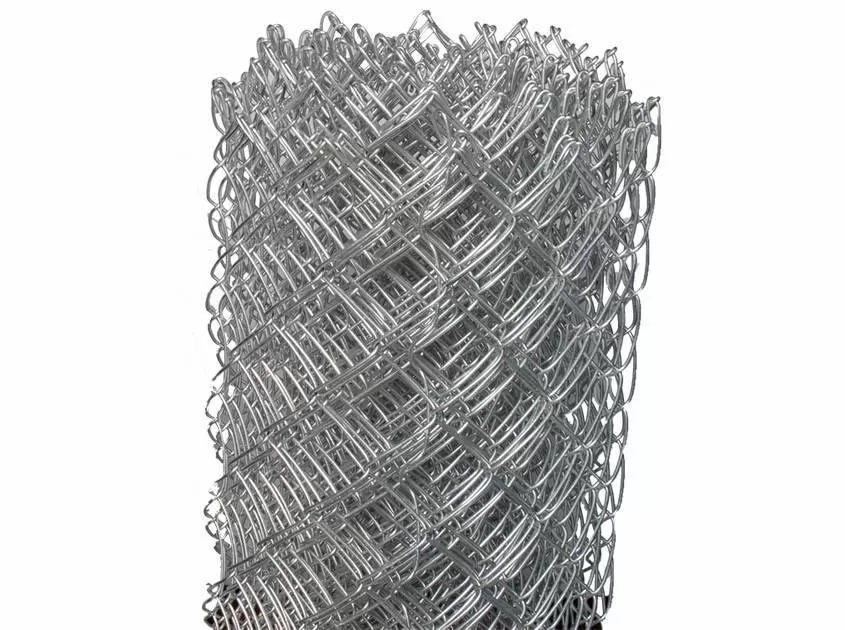

The chain link fence is made of metal wire

Once the galvanized steel wire is acquired, it undergoes the wire drawing process. This process involves pulling the wire through a series of dies to reduce its diameter and increase its length. Wire drawing helps to achieve the desired thickness and tensile strength required for chain link fencing.

After wire drawing, the steel wire is galvanized to enhance its corrosion resistance. Galvanizing involves immersing the wire in a bath of molten zinc, which forms a protective layer on its surface. This zinc coating helps prevent rust and corrosion, extending thelifespan of the chain link fence.

Once the wire is galvanized, it is ready for the weaving process. Chain link fences are typically woven using a machine that forms the distinctive diamond pattern. The weaving machine consists of a series of interconnected parts that guide the wire through the weaving process, creating the mesh pattern characteristic of chain link fences.

Chain link fence is produced by a fully automatic machine.

After weaving, the chain link fence is subjected to tensioning to ensure that it remains taut and stable. Tensioning involves stretching the fence mesh to remove any slack and achieve uniformity. Additionally, excess wire is trimmed to create clean edges and prevent snagging or injury.

In some cases, chain link fences may undergo additional coating processes to enhance their appearance or provide additional protection. This may involve applying a polyester or vinyl coating to the galvanized wire mesh to add color and improve aesthetics. Coating processes vary depending on the desired finish and application requirements.

In addition to the wire mesh, chain link fences may require other components such as posts, rails, and fittings. These components are typically fabricated separately using materials such as galvanized steel or aluminum. Fabrication processes may include cutting, bending, welding, and surface finishing to create the necessary components for fence installation.

Once all the components are ready, the chain link fence is assembled according to the specified design and dimensions. This may involve attaching the mesh to the posts and rails using fittings and fasteners. The assembled fence sections are then packaged and prepared for shipment to customers or installation at the desired location.

Chain link fences are manufactured through a series of carefully orchestrated processes, from selecting raw materials to assembling the finished product. By understanding the manufacturing process, consumers can appreciate the quality and craftsmanship that goes into producing these durable and versatile fencing solutions.

Whether used for residential, commercial, or industrial applications, chain link fences continue to be a popular choice for property enclosures, providing security, visibility, and peace of mind to property owners worldwide.

Qunkun manufactue the following products with complete specifications and good quality: Welded mesh, Hexagonal wire netting, gabion, chain link fence,wire mesh fences, welded wire mesh, welded wire panels, expanded metal mesh, stainless steel wire mesh, Cages, Special material wire mesh, Filters and so on. Our products are widely used in petroleum, chemical, construction, textile, medicine, aviation, aerospace and other industries.

To see all of our chain link fences options online, click here.

Related Articles

Comments

Please Join Us to post.

0