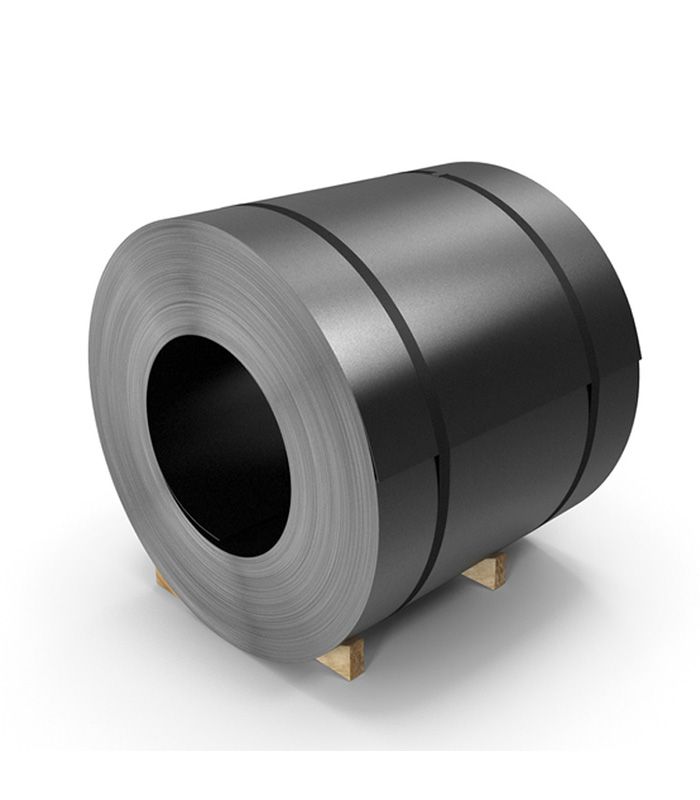

Before we dive into the intricacies of hot rolled steel coil, it's crucial to grasp the fundamentals. Hot rolled steel coil is a versatile and widely used material in various industries, thanks to its unique manufacturing process and remarkable properties.

Hot rolled steel coils are created through a process known as hot rolling. This involves heating a large metal slab to high temperatures, typically around 1700°F (926°C), before passing it through a series of rollers. The intense heat and pressure result in the flattening and shaping of the steel into a coil. This method not only enhances the material's strength but also eliminates impurities, making it exceptionally pure.

One of the primary reasons hot rolled steel coils are favored across industries is their exceptional strength. The intense heat during the rolling process changes the crystalline structure of the steel, aligning its molecules in a way that provides unparalleled strength and durability. This inherent strength makes hot rolled steel coils ideal for applications where structural integrity is paramount.

Hot rolled steel coils offer a plethora of advantages that set them apart from other materials. Let's delve into these benefits:

Hot rolled steel coils are not only robust but also cost-effective. The efficiency of the hot rolling process, along with the abundance of raw materials, results in a material that offers exceptional value for money.

Whether you need sheets, strips, or structural components, hot rolled steel coils can be tailored to your specific requirements. Their versatility allows for customization, making them suitable for diverse applications.

The durability of hot rolled steel coils is unmatched. They can withstand extreme temperatures, heavy loads, and the test of time, ensuring your projects remain sturdy and reliable.

Hot rolled steel coils find extensive use in a wide range of industries due to their unique combination of strength, versatility, and cost-effectiveness. Let's explore some of the key applications where hot rolled steel coils shine:

In the construction industry, structural integrity and load-bearing capacity are non-negotiable. Hot rolled steel coils are a staple in the construction of buildings, bridges, and infrastructure. Their ability to withstand heavy loads and harsh environmental conditions makes them the go-to choice for architects and engineers.

Manufacturers rely on hot rolled steel coils to craft a myriad of products, from automotive components to machinery parts. The material's malleability and strength make it suitable for shaping into various forms, ensuring the end products meet stringent quality standards.

The energy sector heavily relies on hot rolled steel coils for the construction of pipelines. The coils' durability and resistance to corrosion make them ideal for transporting oil, natural gas, and other critical fluids over long distances.

In the automotive industry, where safety and performance are paramount, hot rolled steel coils are used to manufacture vehicle frames and structural components. Their high strength-to-weight ratio contributes to the overall safety and fuel efficiency of automobiles.

In conclusion, hot rolled steel coils are a cornerstone in various industries, thanks to their exceptional strength, versatility, and cost-efficiency. Whether you're involved in construction, manufacturing, or any field that demands robust materials, hot rolled steel coils provide the key to unlocking superior strength and reliability.

So, the next time you embark on a project that requires the utmost in structural integrity, remember the secret to superior strength lies in the power of hot rolled steel coils.

Comments

Please Join Us to post.

0